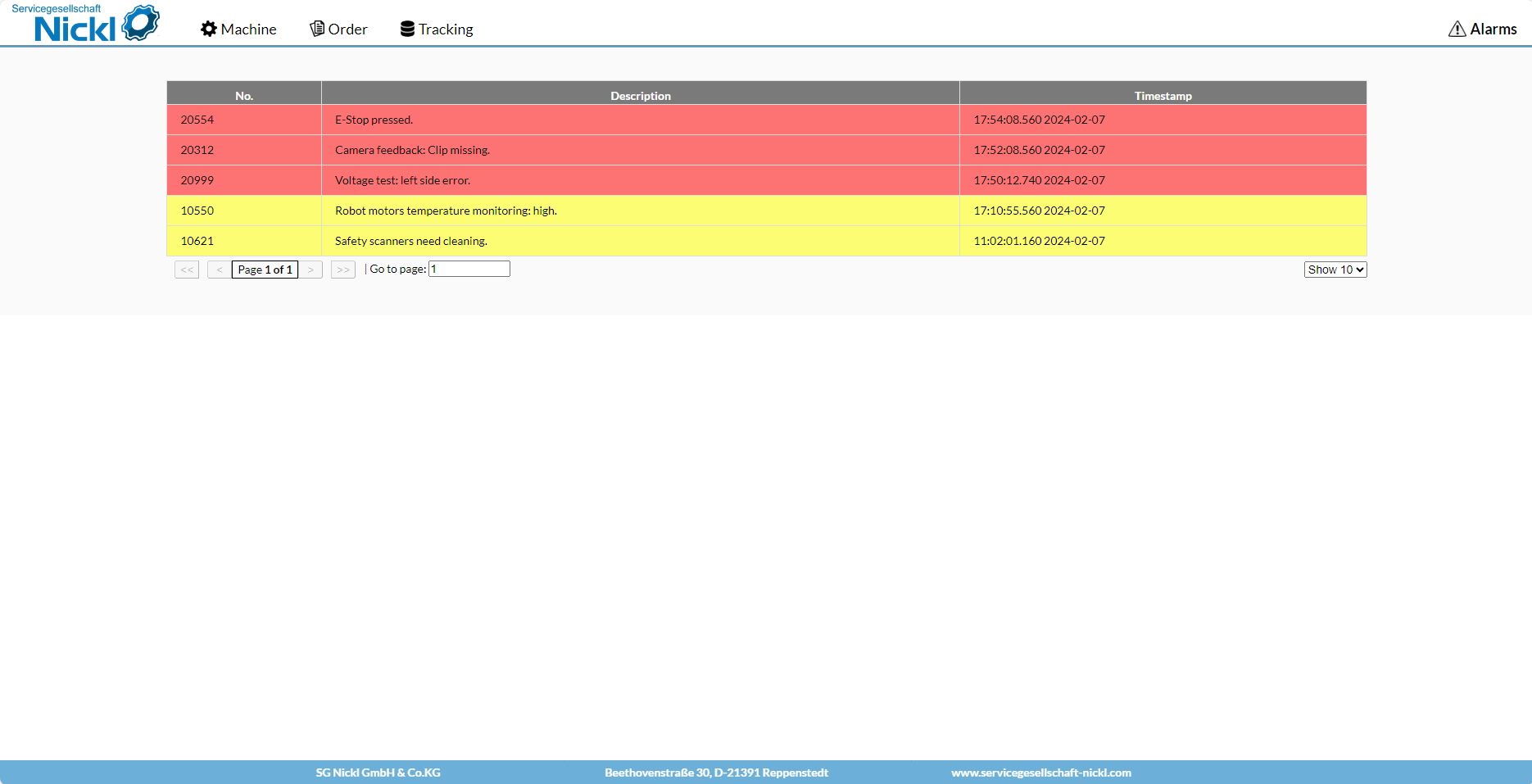

Increasing demands on automation technology in the age of Industry 4.0 are now commonplace. In project planning phases and customer discussions, the aspect of software project planning is missing, although the requirements for integrating a system into the company’s IT are constantly increasing. SG Nickl therefore focuses on internal software know-how for the integration of industrial software solutions in order to be the holistic point of contact for the customer.

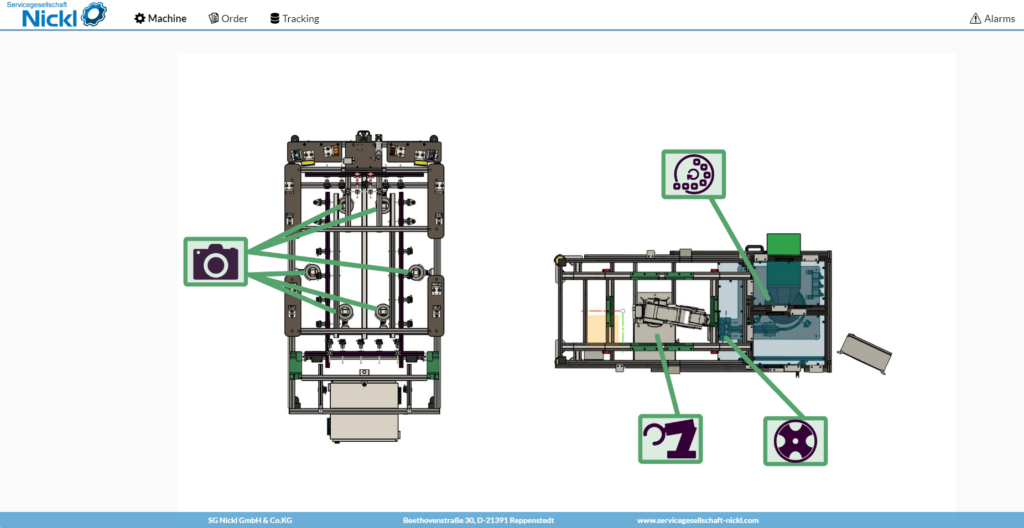

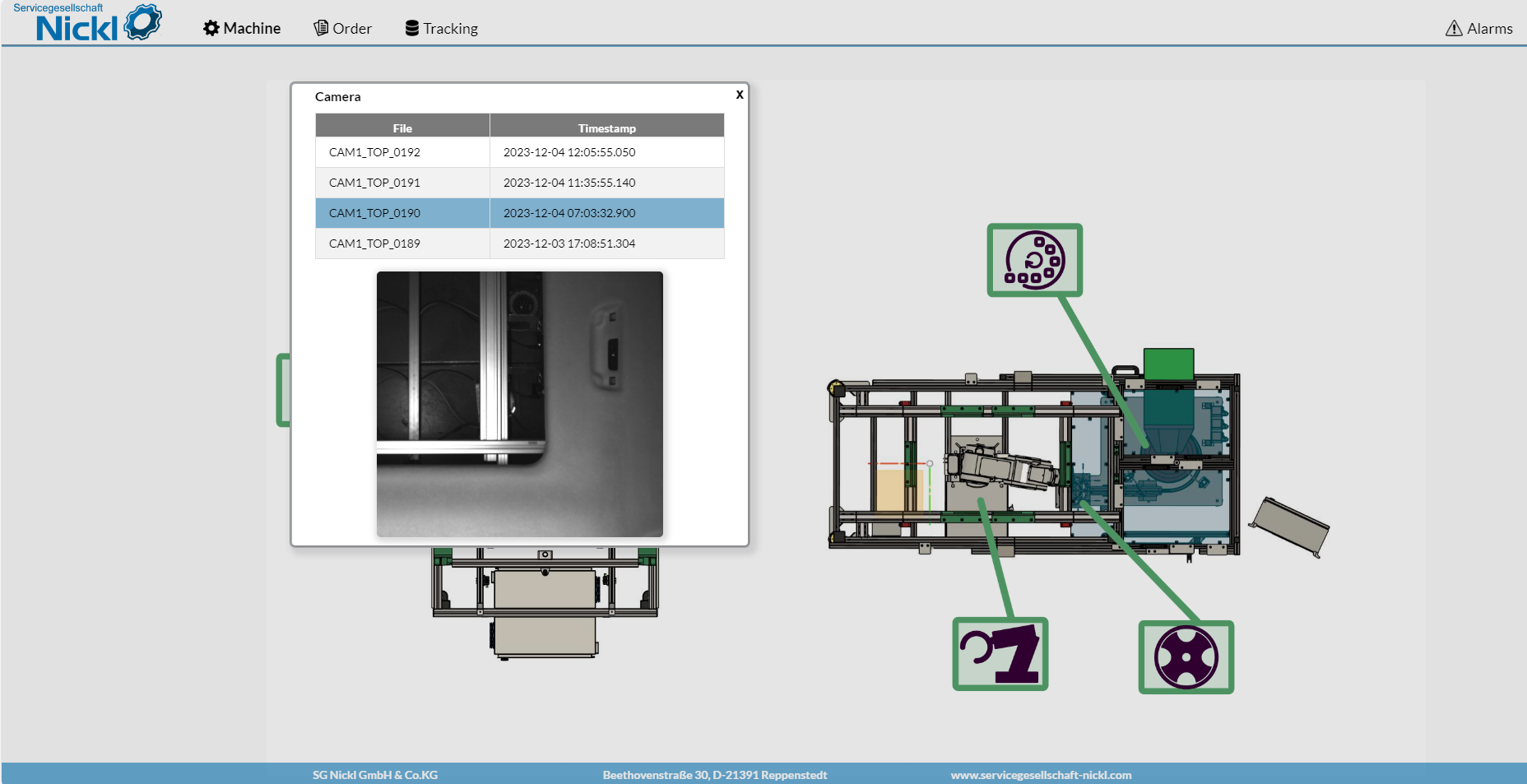

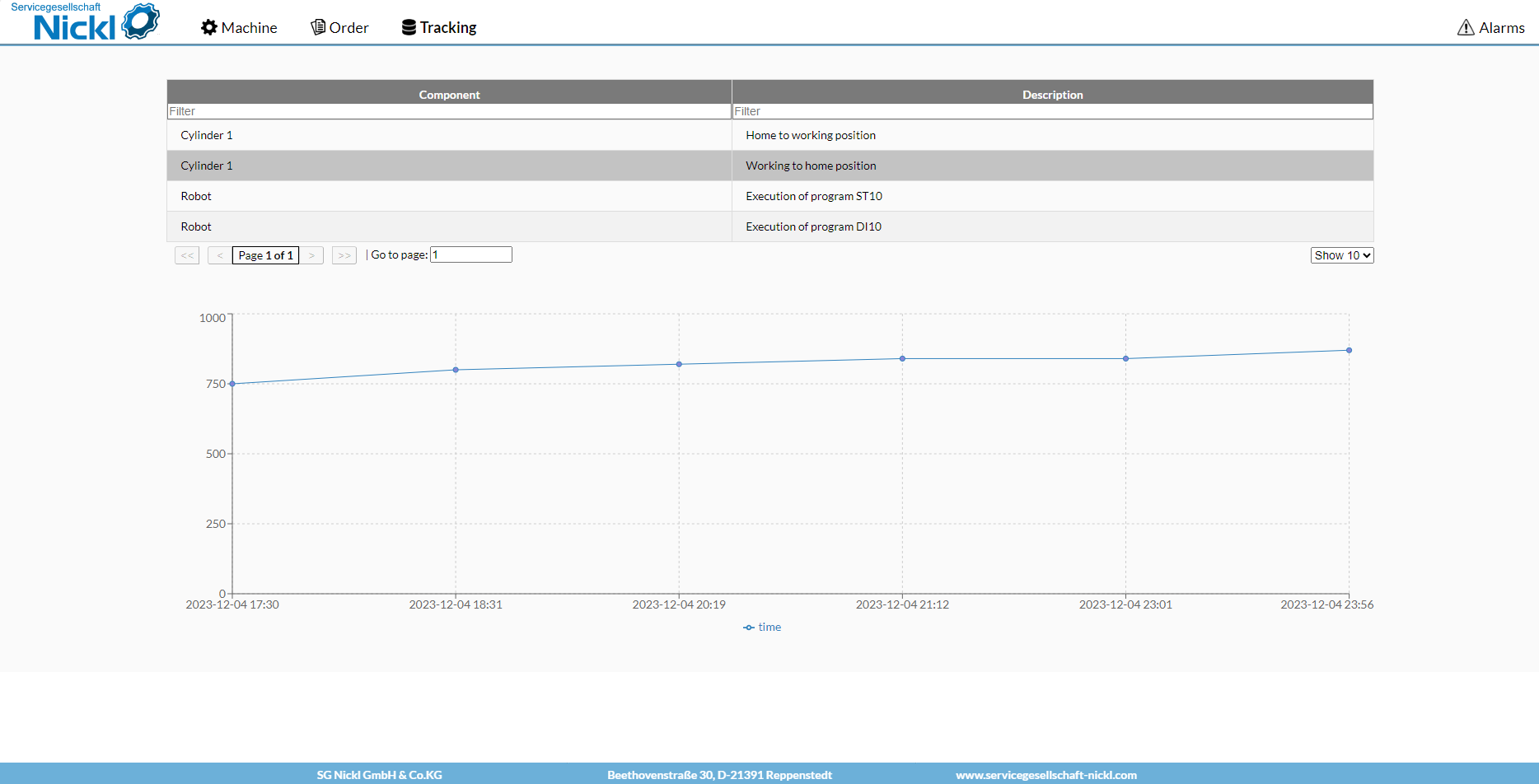

Accordingly, we have PC-based solutions in our portfolio, enabling a transition between physical and virtual environments. The software development offers far more extensive interface options, independence from control technology and the ability to integrate databases such as MySQL, MSSQL or IoTDB. Our solutions offer high scalability for process adaptations, product changes or changes to the workflow.