The Servicegesellschaft Nickl acts globally as machine and plant manufacturer. Our markets are located in Europe, Asia, North- and South America.

The following portfolio presents an exemplary range of the projects that have been successfully implemented over the last few years.

Whether you want us to design smaller assemblies or to plan entire production lines from scratch:

We support you gladly with the realization of your ideas!

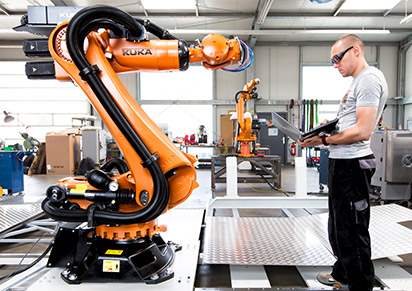

Various projects for the automotive industry:

- Modification of a single color slush machine to dual color via spray application.

- New construction of dual color slush machines with handling systems based on industrial robots (Kuka Titan) or linear technology

- Automation solutions for injection moulding machines

- Fully integrated cleaning systems for Galvano tools

- Powder filling machines with automated weighing and dosing systems.

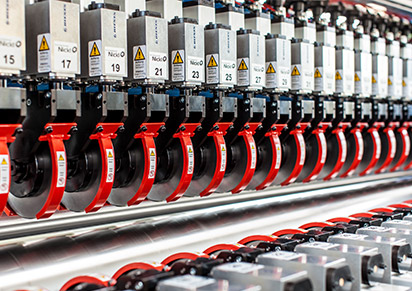

Retrofits for slitting and rewinding machines:

- Modification of drives incl. the implementation of SLS-operation (Safety Limited Speed)

- Modernization of the safety- and control technology as well as the pneumatics

- Integration of a transport crane for the rewind shafts incl. storage solution

- Modernization of the ultrasonic cutting & welding machine

- Optimization of the cutting und scraping unit.

Development of a laboratory coating system:

- Mechanical precision roller adjustment device:

adjustment track 5 mm, accuracy ± 5μm - Chemical-resistant leightweight plastic cover for the nitrogen atmosphere

- Removable teflon side-bulkheads

- Stainless steel worktop and coated stainless steel drip tray for simple cleaning.

- Robust, moveable aluminium sub-construction

New construction of an inspection machine of coupling from drill rods:

- 3-axis linear portal for the test object handling

- Heavy Duty conveyor with inlays for couplings

- Safety-compliant design of the test cabin

- Integration in TEU-Container for shipment

- Darkening of the test cabin through conveyor-synchrony moving light traps

Developement of a hotmelt coating machine:

- Mechanical, thermal stabilized precision roller adjustment device: adjustment track 5 mm, accuracy ± 5μm

- Electrical roll heating, temperature range 80°C to 120°C, control accuracy: ± 2°C

- Removable teflon side-bulkheads

- Pneumatic braked unwind with pneumatic clamps

- Spreader roll with force transducer for web tension feedback control

- Reel Section with web tension feedback controlled asnchronous motor and pneumatic clamps

Design of smaller assemblies and parts:

- Friction elements for rewind shafts of various diameters

- Rewind shaft clamps

- Fixtures for workpiece chucking systems

- Gripper equipment

- New construction of a labelling station

- Manufacturing of replacement parts

- Conveyor technology

- Ladders, lifts and Climb Assistance

- And much more